Choosing a hydraulic pump and motor for industrial applications can be overwhelming because of the numerous options in the market. From different types of hydraulic pumps to shafts, rotations, and brands, finding the best can be a difficult job to meet your requirements. Furthermore, your choice depends on the type of application since different factors influence the choice. Here are vital considerations when choosing a hydraulic pump.

- Hydraulic Pump Types

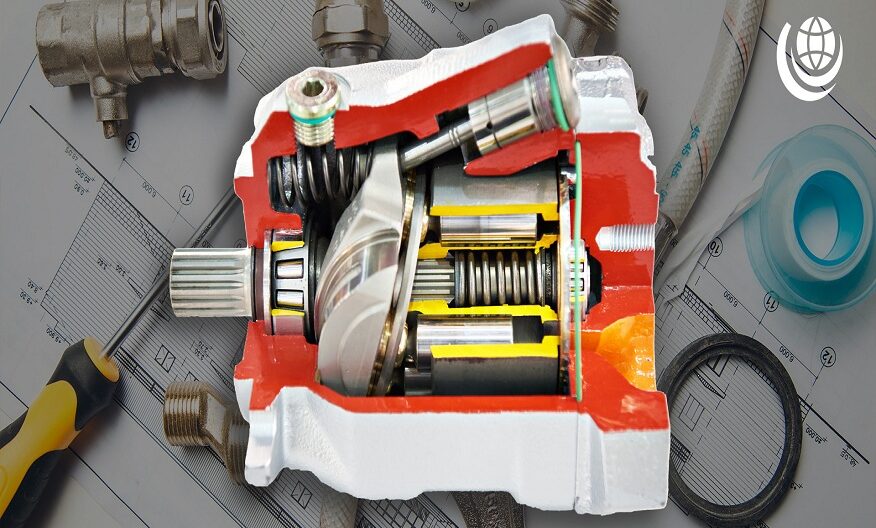

The first step to choosing the right hydraulic pump is to define the purpose of the application. All pumps are designed to move hydraulic fluid through the systems. However, they come in different types based on the applications. The three main types of hydraulic pumps are gear pumps, pistons, and vanes. Therefore, know the best pump and motor type that fit your application. It is crucial to be careful with your selection at this stage to ensure your hydraulic motor works at its optimum capability.

- Fluid Type

It is crucial to confirm that the material used to make the pump is attuned to different types of fluids in the system. The compatibility also depends on the kind of fluid in the system. Therefore, when choosing the pump, consider liquid properties like viscosity, liquid temperature, vapor pressure, or the solids in the liquid. It is also crucial to check if the liquid is abrasive or sensitive to shear.

- Pressure

The pressure rate determines the pressure the pump can hold without leaking or damaging internal parts. So, the best way to know the amount of pressure it can handle is to check the fittings, interior elements, and length. One important thing you must remember is that the pressure rate is stated under the same temperature.

- Efficiency

Confirming the pump’s efficiency is vital to ensure you spend less for more. So, when checking efficiency, look at things like volumetric and mechanical efficiency. The efficiency of the pipe will determine how much work it can do.

- Capacity

The volumetric output and pump capacity determine its performance. It is also advisable to check the flow rate. Pumps with a low flow rate and recommended by the manufacturer even though they take time to pump the liquid. On the other hand, pumps with a higher flow rate cost more. Therefore, consider your budget when picking a pump based on the capacity.

- Drive Speed

A typical hydraulic pump runs at 1200 0r 1800 rpm. However, mobile hydraulic pumps with internal combustion can run up to 2000 rpm. Industrial pumps also go at 4000rpm for more efficiency. It is crucial to check the maximum pressure the pump can withstand to avoid issues.

- Pump Placement

Pump placement will also determine the type of hydraulic pump you will go for. Where do you plan to put the pump? If you plan to keep it outside, you need to choose a pump that can withstand environmental conditions like dust and debris. You must also ensure it has other features that protect it from freezing.

Summary

You should look at these seven crucial things when selecting a hydraulic pump. It is also wise to consult an experienced hydraulic pump contractor to help pick a pump that will serve well.